The lifespan of your tools are one of the most important factors to consider since you do not want to purchase a tool only to use it for a week because it is not viable anymore. By reading this article, you will learn about the various factors that affect the longevity of your tools.

The continued use of machinery in our everyday activities has brought about the need to use tools to repair, make, or install items. There are various power tools available in Kenya today for different purposes, and depending they can range from being relatively affordable to be quite costly.

Whether the total tools you require are personal or professional, just knowing how to use them appropriately is not enough. You also have to familiarize yourself with the various factors that affect the longevity of your tools. Below are factors that affect the longevity of the total tools.

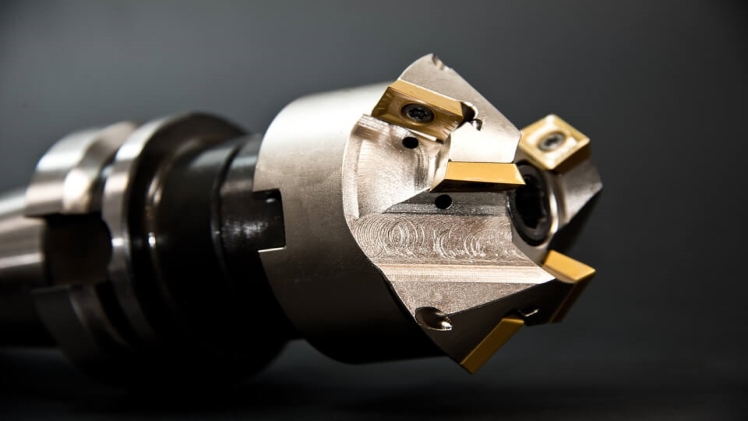

The Material of the Tool

The life span of the Total tools Kenya is affected by the material used to make them. The materials used are supposed to be strong enough to execute the jobs done needed to be done by the tool. Moreover, the tool should be appropriately machined. Having an adequately made tool from quality materials is the first thing that warrants the longevity of your tool.

Cutting Speed

The cutting speed of a toll highly influences the lifespan of your tool. Increasing the cutting speed decreases the tool’s life. The tool’s wear depends on the cutting speed since increasing the cutting speed leads to a rise in temperature, increasing wear reducing the tool’s lifespan.

Read More: World Latest Business Website schulist.info and theexpressreview.com also check health blog site healthylifey.com

Feed Rate and Cut Depth

An increase in the feed rate decreases the tool’s life because adding feed results in a more confined action that heats the tool at its chip interface. This is also the case for cut depth. If the depth is increased for the same cut and feed decreased, the cutting speed will increase.

The Physical Property of the Workpiece

Total tools Kenya lifespan correlates with the workpiece microstructure. A poor tool life may be a result of the matrix having hard micro constituents.

Also, larger grain size increases the tool’s life.

The Angle and Shape of the Tool

Increasing the back rake angle decreases the cutting force due to a small shear strain. The shear strain is higher when you use the negative rake angle; however, you can experience a higher cutting force at the negative rake angle than positive rake angles.

A large side rake angle will produce chipping, while a smaller rake angle will produce more heat or excessively wear the tool, deforming it.

Also, increasing the nose radius increases the tool’s life. A small nose will result in excessive stress concentration and an increase in the heat generated.

Lubricant Effect

You will decrease the cutting forces by lubricating. The impact of the cutting fluid is more important over the cutting speed’s lower range than at higher cutting speeds. The cutting fluid acts as a lubricant at low rates, reducing friction at the interface of the tool and chip.

Cutting Nature

The cutting nature of a tool significantly affects its lifespan. Continuous cutting increases the tool’s life, whereas intermittent cutting decreases it. Intermittent cutting causes a much earlier failure since it gives regular impacts on the tool.

Conclusion

If you would like to enjoy using your tools entirely, you might want to consider all the factors that affect the tool’s life. For more about tools, check https://powertools.co.ke

Thenewssources Best News Website Also Read More About ibloghub.

Check This Link thewebgross